/3d-printing-528445767-5b99c1ea46e0fb0025c6935d.jpg)

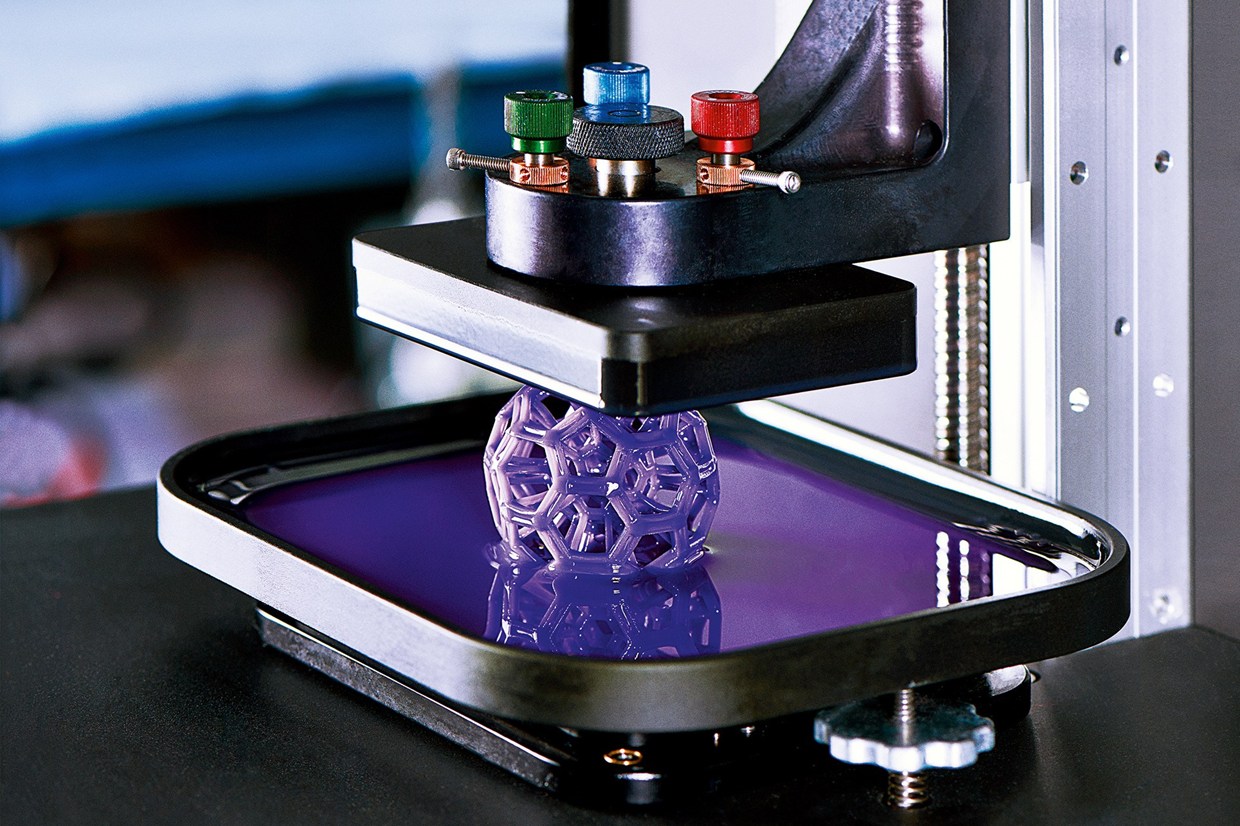

Here, we can see Carbon 3D’s CLIP technology in action: This eliminates the need for a peeling mechanism, such as the one on the Form 2. Or basically, the pool of resin lies on an oxygenated surface, keeping it from solidifying (sticking), and the print head pulls up the solidifying resin, growing the object.

Speed up 3d printer movie#

As a series of cross-sectional images of a 3D model is played like a movie into the resin pool from underneath, the physical object emerges continuously from just above the dead zone.”

By controlling the oxygen flux through the window, CLIP creates a “dead zone” in the resin pool just tens of microns thick (about 2-3 diameters of a red blood cell) where photo-polymerisation cannot occur. Carbon 3D explains, “At the heart of the CLIP process is a special window that is transparent to light and permeable to oxygen, much like a contact lens. By carefully balancing the interaction between UV light and oxygen, objects are grown from a pool of liquid resin 25-100 times faster than stereolithography printers. UV light is the photo-polymerisation agent while oxygen is the inhibiting agent. CLIP at first glance is similar to stereolithography (SLA) in that it uses UV light to cure a resin, but it also uses another inhibiting agent, and that agent is oxygen. The second technology promising huge speeds comes from Silicon Valley-based Carbon 3D, who have $100 million in funding from Google Ventures.Ĭarbon 3D’s technology, Liquid Interface Production Technology (CLIP), promises print speeds 25-100 times faster than conventional 3D printing and at a quality suitable for end-use parts. Here, we can see the D3D ONE EVO powered by Create it REAL in action:Ĭarbon3D’s Liquid Interface Production Technology (CLIP) At those speeds, a complex object that would usually take 240 minutes to print at a speed of 180 mm/sec would be printed in just 24 minutes. What’s even more staggering, is that Create it REAL plan on taking this all the way up to 1800 mm/sec. The control board has already been successfully trialled by Italy-based company Dynamo 3D, who used the board in one of their D3D ONE EVO printers to print objects at 455 mm/sec. Of course, the control board is limited by current extruder technology, but that doesn’t dampen its amazing potential. With the capability to boost print speeds to a staggering 455 mm/sec in any 3D printer, as well as significantly reduce vibration during the print process, Create it REAL’S 3D RTP was met with a lot of media coverage. In 2015, Denmark-based company Create it REAL announced a new control board, the 3D RTP (Real Time Processor), which is capable of acting as the control module for all FFF, FDM and SLA 3D printers.

The first of these isn’t courtesy of a fancy new printing process, but a humble control board from a company called Create it REAL. It may come as a surprise then that there are a few technologies out there right now that go way beyond those speeds. That’s actually a respectable speed, but for some using it for manufacturing purposes where speed is of the essence, it is not enough. At that speed, it will take 1.5 hours to build Formlabs’ Twisted Rook, or if you print it at 20 microns, it will take around 8.5 hours. For example, the build speed of the Formlabs Form 2 is 1-3 cm/hour along the Z axis, when printing at 100 micron. So if you are printing at 20-100 micron, or 0.02-0.1mm, it is going to take you hours to print a complex object. That is actually quite fast, however that speed is offset by layer height.įor truly detailed parts, you need to print with incredibly thin layers.

The typical print speed for a desktop 3D printer today is in the range of 50-100 mm/sec (that’s 50-100 mm of filament per second). Our only real complaint with 3D printing – a complaint shared by many people – is how long it takes to print something right now. If there is one area of 3D printing where things will improve considerably in the next ten years, that area is speed. We will be astonished by how far things have progressed. The success of these products has been incredible, and ten years from now, we will probably look back at the 3D printers of today with the same marvel. Who knew that these would become as popular as they are today? Absolutely nobody. In 2006, ten years ago, Blu-Ray was announced, YouTube was launched and Apple released the first Macbook.

0 kommentar(er)

0 kommentar(er)